Our Process

At INDEX, we provide a fully integrated precast construction solution, managing every phase of the project—from concept to execution. Our three-step process ensures efficiency, precision, and seamless project delivery.

Every successful project begins with smart design. Our in-house technical office, staffed by highly skilled engineers, provides complete precast design solutions, ensuring structural integrity and optimal efficiency.

We also assist with feasibility studies and value engineering, helping clients convert traditional construction designs into precast, increasing efficiency and accelerating project timelines. Whether designing structural, infrastructure, or architectural elements, we ensure every component meets the highest standards.

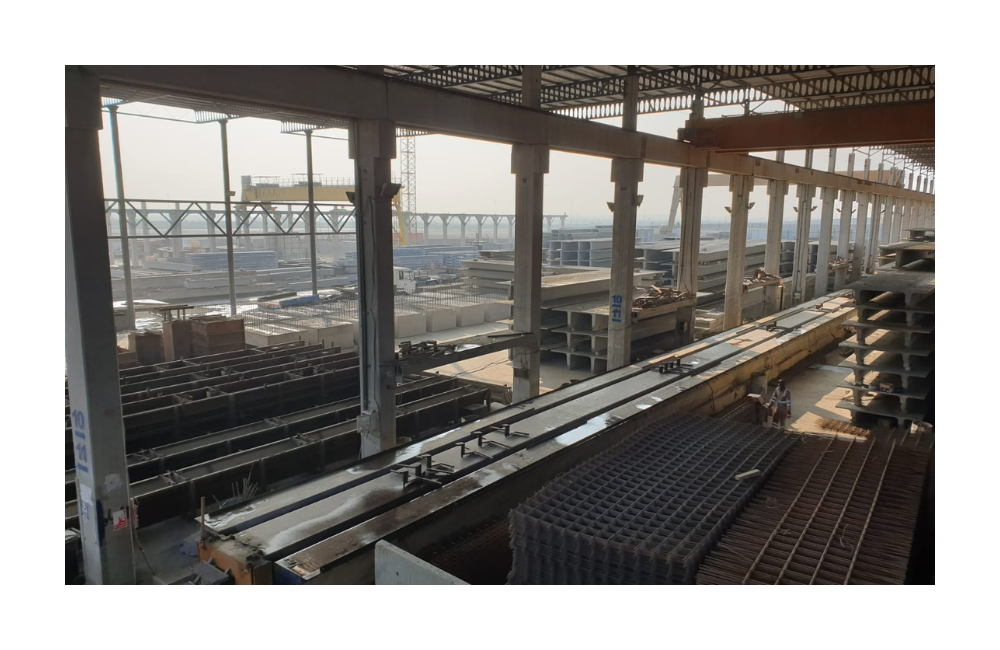

With a daily production capacity exceeding 500 cubic meters, our state-of-the-art manufacturing facilities are equipped to produce a wide range of precast elements—from structural components to infrastructure solutions and GFRC cladding.

Using advanced precasting machinery, techniques, and stringent quality control, we ensure every unit is manufactured to precise specifications, built for durability, and ready for seamless installation

We don’t just manufacture—we deliver and install precast. With our own fleet of trucks, trailers, and mobile cranes, we handle logistics in-house, ensuring that every order arrives on time, every time. Our experienced site engineers, foremen, and installation teams work with precision, guaranteeing a smooth and efficient erection process. Our vertically integrated supply chain means no delays, no excuses- just execution.

From concept to completion, INDEX delivers precast solutions that redefine efficiency, durability, and precision.